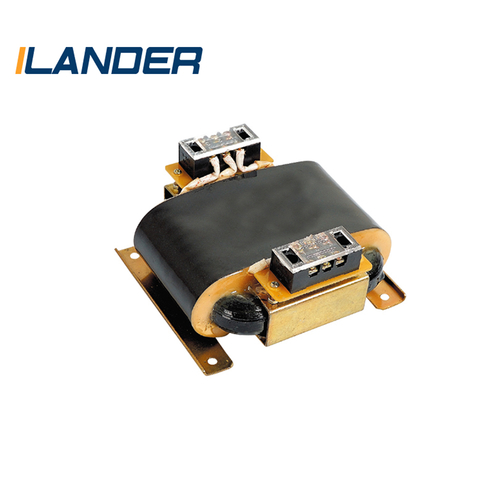

Toroidal transformers are a critical component in a wide range of electronic and electrical applications, from audio equipment and medical devices to industrial power supplies and renewable energy systems. Unlike traditional laminated transformers, toroidal transformers offer superior efficiency, compact size, and reduced electromagnetic interference (EMI). As demand for high-performance, energy-efficient power solutions grows, selecting the right toroidal transformer manufacturer becomes crucial for engineers, designers, and businesses.

Toroidal transformers are distinguished by their doughnut-shaped core, which provides several benefits over conventional transformers:

Higher Efficiency

The continuous winding and symmetrical core design minimize magnetic flux leakage, resulting in energy efficiency levels exceeding 95%. This makes them ideal for applications where power loss must be minimized.

Compact and Lightweight

The toroidal shape allows for a more compact design, reducing the overall size and weight of the transformer. This is particularly beneficial in space-constrained applications like medical equipment and high-end audio systems.

Lower Electromagnetic Interference (EMI)

The closed-loop core significantly reduces EMI, making toroidal transformers suitable for sensitive electronics where noise suppression is critical.

Cooler Operation

Due to their efficient design, toroidal transformers generate less heat, reducing the need for additional cooling mechanisms and improving long-term reliability.

Given these advantages, industries such as aerospace, telecommunications, and renewable energy increasingly rely on toroidal transformers for their power conversion needs.

Selecting the right manufacturer is essential to ensure product quality, reliability, and performance.

1. Expertise and Experience

Look for manufacturers with a proven track record in designing and producing toroidal transformers.

Companies with decades of experience often have refined manufacturing processes and better quality control.

2. Customization Capabilities

The best manufacturers offer custom toroidal transformers tailored to specific voltage, current, and frequency requirements.They should provide engineering support to optimize designs for efficiency and thermal performance.

3. Compliance with Industry Standards

Reputable manufacturers adhere to international standards such as UL, CE, RoHS, and ISO certifications.Compliance ensures safety, reliability, and compatibility with global markets.

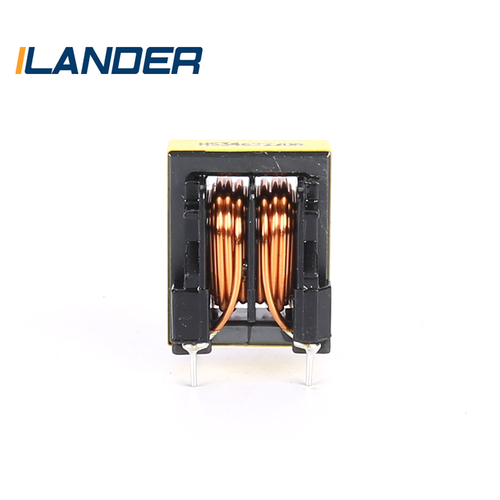

4. Advanced Manufacturing Techniques

High-quality toroidal transformers require precision winding, vacuum impregnation, and rigorous testing.Manufacturers using automated winding machines and computer-aided design (CAD) tools can ensure consistency and precision.

5. Testing and Quality Assurance

Reliable manufacturers perform extensive testing, including:

Hi-Pot (Dielectric Strength) Testing

Inductance and Leakage Current Measurements

Thermal Cycling and Vibration Testing

These tests ensure durability and performance under real-world conditions.

6. Global Supply Chain and Lead Times

Manufacturers with a robust supply chain can deliver products on time, even for large-scale orders.Short lead times are crucial for industries with fast-paced production cycles.

Toroidal transformers play a vital role in modern electronics, offering unmatched efficiency, compactness, and performance.

As technology advances, the demand for high-quality toroidal transformers will only grow, making it essential to partner with manufacturers that can deliver reliability, efficiency, and scalability. Whether for industrial, medical, or consumer applications, investing in the right supplier ensures long-term success in your electronic designs.

English

English Español

Español