In modern power systems and industrial automation, accurate and reliable current measurement is not only the basis for safe operation, but also an important prerequisite for intelligent control and energy optimization. As a bridge between high voltage and high current equipment and low voltage measurement systems, Current Transformer plays a vital role. It is not only ubiquitous in power transmission and distribution systems, but also plays an increasingly core role in smart grids, industrial control, rail transportation and new energy.

Current Transformer, or CT for short, is essentially an electromagnetic device that converts high current into low current signals. Since the current of thousands of amperes in modern power systems cannot be directly processed by conventional measurement equipment, it must be converted into small and precise measurable values through CT, thereby realizing indirect monitoring and control of the original current. This conversion requires not only high precision, but also insulation safety and electrical isolation, so the design and manufacturing standards of CT are very strict.

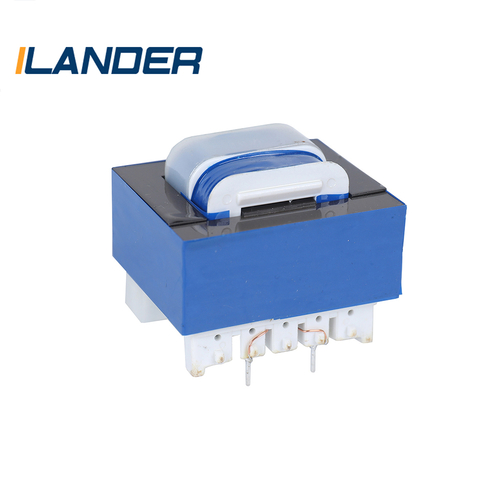

From a structural point of view, a current transformer usually consists of a magnetic core passing through the primary conductor and a secondary winding wound on the magnetic core. The primary conductor can be a cable, a busbar, or even a winding, carrying the operating current to be measured. The secondary winding is responsible for inducing a current signal proportional to the primary current. This ratio - usually a conversion ratio such as 1000:5 or 3000:1 - not only determines the amplitude of the output signal, but also defines the calibration basis of the measurement system.

A key advantage of CTs is their electrical isolation characteristics. When measuring current in high-voltage systems, using CTs can effectively avoid the risk of electric shock to measuring instruments and operators. Through magnetic coupling, it completely isolates the primary side from the secondary side, ensuring that the entire measurement system is safe and stable. This feature is particularly important in high-voltage substations, railway traction power supply systems, and large motor control.

When selecting CTs, engineers need to consider not only the ratio, accuracy level, and load capacity, but also their saturation characteristics and phase error. Especially in protection systems, if the CT saturates when the current changes suddenly, it will directly affect the action judgment of the relay protection device and even cause equipment failure. High-accuracy, low hysteresis loss material selection, reasonable core design, and process control are crucial.

The installation environment and method of CT also have a direct impact on its performance. In outdoor high humidity and high temperature or strong electromagnetic interference environment, CT may face problems such as insulation aging and core corrosion. Therefore, CT with good sealing performance, high protection level, and environmental resistance of materials can often serve the system longer and more stably.

With the increasing requirements for energy efficiency and power safety, Current Transformer is no longer just a measurement tool, but also an important "tentacle" for intelligent systems to perceive the world. It silently records every fluctuation of the current, provides data support for the upper control system, and also builds the first line of defense for power safety.

English

English Español

Español